Page 343 - THREADING CATALOG

P. 343

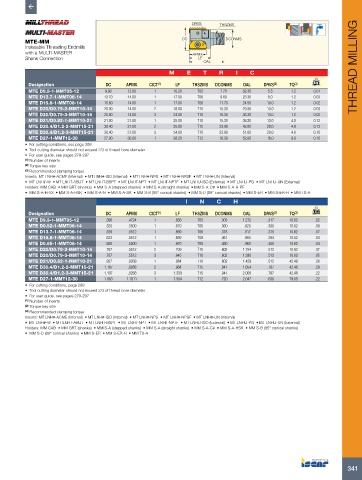

DRVS THSZMS

MTE-MM DC DCONMS

Indexable Threading Endmills

with a MULTI-MASTER APMX

Shank Connection LF

OAL

M E T R I C THREAD MILLING

Designation DC APMX CICT (1) LF THSZMS DCONMS OAL DRVS (2) TQ (3) kg

MTE D9.9-1-MMT05-12 9.90 12.00 1 16.20 T05 7.70 32.30 5.5 1.2 0.01

MTE D13.7-1-MMT06-14 13.70 14.00 1 17.00 T06 9.60 23.30 8.0 1.2 0.03

MTE D15.8-1-MMT08-14 15.80 14.00 1 17.00 T08 11.70 24.50 10.0 1.2 0.02

MTE D20/D0.79-2-MMT10-14 20.00 14.00 2 18.00 T10 15.30 29.30 13.0 1.2 0.03

MTE D20/D0.79-3-MMT10-14 20.00 14.00 3 24.00 T10 15.30 35.30 13.0 1.2 0.02

MTE D21/D0.82-1-MMT10-21 21.00 21.00 1 25.00 T10 15.30 36.30 13.0 4.8 0.12

MTE D30.4/D1.2-2-MMT15-21 30.40 21.00 2 25.00 T15 23.90 42.00 20.0 4.8 0.13

MTE D30.4/D1.2-3-MMT15-21 30.40 21.00 3 34.00 T15 23.90 51.00 20.0 4.8 0.10

MTE D27-1-MMT12-30 27.00 30.00 1 38.20 T12 18.30 52.00 16.0 9.0 0.10

• For cutting conditions, see page 299

• Tool cutting diameter should not exceed 2/3 of thread bore diameter

• For user guide, see pages 279-297

(1) Number of inserts

(2) Torque key size

(3) Recommended clamping torque

Inserts: MT LNH#-ACME (Internal) • MT LNH#-ISO (Internal) • MT LNH#-NPS • MT LNH#-NPSF • MT LNH#-UN (Internal)

• MT LNH#-W • MT LNHT-ABUT • MT LNHT-BSPT • MT LNHT-NPT • MT LNHT-NPTF • MT LNHU-ISO (External) • MT LNHU-PG • MT LNHU-UN (External)

Holders: MM CAB • MM GRT (shanks) • MM S-A (stepped shanks) • MM S-A (straight shanks) • MM S-A-C# • MM S-A-H-PF

• MM S-A-H-VX • MM S-A-HSK • MM S-A-N • MM S-A-SK • MM S-B (85° conical shanks) • MM S-D (89° conical shanks) • MM S-ER • MM S-ER-H • MM TS-A

I N C H

Designation DC APMX CICT (1) LF THSZMS DCONMS OAL DRVS (2) TQ (3) Lbs

MTE D9.9-1-MMT05-12 .390 .4724 1 .638 T05 .303 1.272 .217 10.62 .02

MTE D0.52-1-MMT06-14 .520 .5500 1 .670 T06 .360 .920 .300 10.62 .09

MTE D13.7-1-MMT06-14 .539 .5512 1 .669 T06 .378 .917 .315 10.62 .07

MTE D15.8-1-MMT08-14 .622 .5512 1 .669 T08 .461 .965 .394 10.62 .04

MTE D0.65-1-MMT08-14 .650 .5500 1 .670 T08 .480 .960 .400 10.62 .04

MTE D20/D0.79-2-MMT10-14 .787 .5512 2 .709 T10 .602 1.154 .512 10.62 .07

MTE D20/D0.79-3-MMT10-14 .787 .5512 3 .945 T10 .602 1.390 .512 10.62 .05

MTE D21/D0.82-1-MMT10-21 .827 .8268 1 .984 T10 .602 1.429 .512 42.48 .26

MTE D30.4/D1.2-2-MMT15-21 1.197 .8268 2 .984 T15 .941 1.654 .787 42.48 .29

MTE D30.4/D1.2-3-MMT15-21 1.197 .8268 3 1.339 T15 .941 2.008 .787 42.48 .22

MTE D27-1-MMT12-30 1.063 1.1811 1 1.504 T12 .720 2.047 .630 79.65 .22

• For cutting conditions, page 299

• Tool cutting diameter should not exceed 2/3 of thread bore diameter

• For user guide, see pages 279-297

(1) Number of inserts

(2) Torque key size

(3) Recommended clamping torque

Inserts: MT LNH#-ACME (Internal) • MT LNH#-ISO (Internal) • MT LNH#-NPS • MT LNH#-NPSF • MT LNH#-UN (Internal)

• MT LNH#-W • MT LNHT-ABUT • MT LNHT-BSPT • MT LNHT-NPT • MT LNHT-NPTF • MT LNHU-ISO (External) • MT LNHU-PG • MT LNHU-UN (External)

Holders: MM CAB • MM GRT (shanks) • MM S-A (stepped shanks) • MM S-A (straight shanks) • MM S-A-C# • MM S-A-HSK • MM S-B (85° conical shanks)

• MM S-D (89° conical shanks) • MM S-ER • MM S-ER-H • MM TS-A

341