Page 400 - THREADING CATALOG

P. 400

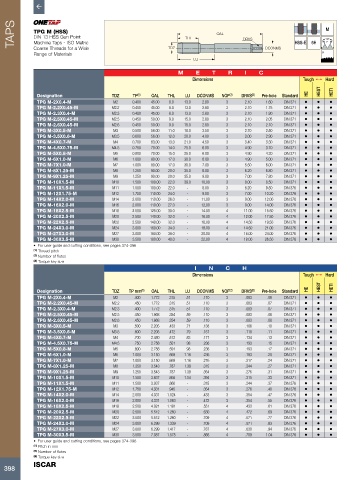

TAPS TPG M (HSS) THL OAL DRVS HSS-E 6H M P

DIN 13 HSS Gun Point

60˚

Machine Taps - ISO Metric

Coarse Threads for a Wide

Range of Materials TDZ DCONMS B

LU

M E T R I C

Dimensions Tough 1 Hard

Designation TDZ TP (1) OAL THL LU DCONMS NOF (2) DRVS (3) Pre-hole Standard HE HEST HETI

TPG M-2X0.4-M M2 0.400 45.00 8.0 13.0 2.80 3 2.10 1.60 DIN 371 • • •

TPG M-2.2X0.45-M M2.2 0.450 45.00 8.0 13.0 2.80 3 2.10 1.75 DIN 371 • • •

TPG M-2.3X0.4-M M2.3 0.400 45.00 8.0 13.0 2.80 3 2.10 1.90 DIN 371 • • •

TPG M-2.5X0.45-M M2.5 0.450 50.00 9.0 15.0 2.80 3 2.10 2.05 DIN 371 • • •

TPG M-2.6X0.45-M M2.6 0.450 50.00 9.0 15.0 2.80 3 2.10 2.10 DIN 371 • • •

TPG M-3X0.5-M M3 0.500 56.00 11.0 18.0 3.50 3 2.70 2.50 DIN 371 • • •

TPG M-3.5X0.6-M M3.5 0.600 56.00 12.0 20.0 4.00 3 3.00 2.90 DIN 371 • • •

TPG M-4X0.7-M M4 0.700 63.00 13.0 21.0 4.50 3 3.40 3.30 DIN 371 • • •

TPG M-4.5X0.75-M M4.5 0.750 70.00 14.0 25.0 6.00 3 4.90 3.70 DIN 371 • • •

TPG M-5X0.8-M M5 0.800 70.00 15.0 25.0 6.00 3 4.90 4.20 DIN 371 • • •

TPG M-6X1.0-M M6 1.000 80.00 17.0 30.0 6.00 3 4.90 5.00 DIN 371 • • •

TPG M-7X1.0-M M7 1.000 80.00 17.0 30.0 7.00 3 5.50 6.00 DIN 371 • • •

TPG M-8X1.25-M M8 1.250 90.00 20.0 35.0 8.00 3 6.20 6.80 DIN 371 • • •

TPG M-9X1.25-M M9 1.250 90.00 20.0 35.0 9.00 3 7.00 7.80 DIN 371 • • •

TPG M-10X1.5-M M10 1.500 100.00 22.0 39.0 10.00 3 8.00 8.50 DIN 371 • • •

TPG M-11X1.5-M M11 1.500 100.00 22.0 - 8.00 3 6.20 9.50 DIN 376 • • •

TPG M-12X1.75-M M12 1.750 110.00 24.0 - 9.00 3 7.00 10.20 DIN 376 • • •

TPG M-14X2.0-M M14 2.000 110.00 26.0 - 11.00 3 9.00 12.00 DIN 376 • • •

TPG M-16X2.0-M M16 2.000 110.00 27.0 - 12.00 3 9.00 14.00 DIN 376 • • •

TPG M-18X2.5-M M18 2.500 125.00 30.0 - 14.00 4 11.00 15.50 DIN 376 • • •

TPG M-20X2.5-M M20 2.500 140.00 32.0 - 16.00 4 12.00 17.50 DIN 376 • • •

TPG M-22X2.5-M M22 2.500 140.00 32.0 - 18.00 4 14.50 19.50 DIN 376 • • •

TPG M-24X3.0-M M24 3.000 160.00 34.0 - 18.00 4 14.50 21.00 DIN 376 • • •

TPG M-27X3.0-M M27 3.000 160.00 36.0 - 20.00 4 16.00 24.00 DIN 376 • • •

TPG M-30X3.5-M M30 3.500 180.00 40.0 - 22.00 4 18.00 26.50 DIN 376 • • •

• For user guide and cutting conditions, see pages 374-396

(1) Thread pitch

(2) Number of flutes

(3) Torque key size

I N C H

Dimensions Tough 1 Hard

Designation TDZ TP mm (1) OAL THL LU DCONMS NOF (2) DRVS (3) Pre-hole Standard HE HEST HETI

TPG M-2X0.4-M M2 .400 1.772 .315 .51 .110 3 .083 .06 DIN 371 • • •

TPG M-2.2X0.45-M M2.2 .450 1.772 .315 .51 .110 3 .083 .07 DIN 371 • • •

TPG M-2.3X0.4-M M2.3 .400 1.772 .315 .51 .110 3 .083 .07 DIN 371 • • •

TPG M-2.5X0.45-M M2.5 .450 1.968 .354 .59 .110 3 .083 .08 DIN 371 • • •

TPG M-2.6X0.45-M M2.6 .450 1.968 .354 .59 .110 3 .083 .08 DIN 371 • • •

TPG M-3X0.5-M M3 .500 2.205 .433 .71 .138 3 .106 .10 DIN 371 • • •

TPG M-3.5X0.6-M M3.5 .600 2.205 .472 .79 .157 3 .118 .11 DIN 371 • • •

TPG M-4X0.7-M M4 .700 2.480 .512 .83 .177 3 .134 .13 DIN 371 • • •

TPG M-4.5X0.75-M M4.5 .750 2.756 .551 .98 .236 3 .193 .15 DIN 371 • • •

TPG M-5X0.8-M M5 .800 2.756 .591 .98 .236 3 .193 .17 DIN 371 • • •

TPG M-6X1.0-M M6 1.000 3.150 .669 1.18 .236 3 .193 .20 DIN 371 • • •

TPG M-7X1.0-M M7 1.000 3.150 .669 1.18 .276 3 .217 .24 DIN 371 • • •

TPG M-8X1.25-M M8 1.250 3.543 .787 1.38 .315 3 .244 .27 DIN 371 • • •

TPG M-9X1.25-M M9 1.250 3.543 .787 1.38 .354 3 .276 .31 DIN 371 • • •

TPG M-10X1.5-M M10 1.500 3.937 .866 1.54 .394 3 .315 .33 DIN 371 • • •

TPG M-11X1.5-M M11 1.500 3.937 .866 - .315 3 .244 .37 DIN 376 • • •

TPG M-12X1.75-M M12 1.750 4.331 .945 - .354 3 .276 .40 DIN 376 • • •

TPG M-14X2.0-M M14 2.000 4.331 1.024 - .433 3 .354 .47 DIN 376 • • •

TPG M-16X2.0-M M16 2.000 4.331 1.063 - .472 3 .354 .55 DIN 376 • • •

TPG M-18X2.5-M M18 2.500 4.921 1.181 - .551 4 .433 .61 DIN 376 • • •

TPG M-20X2.5-M M20 2.500 5.512 1.260 - .630 4 .472 .69 DIN 376 • • •

TPG M-22X2.5-M M22 2.500 5.512 1.260 - .709 4 .571 .77 DIN 376 • • •

TPG M-24X3.0-M M24 3.000 6.299 1.339 - .709 4 .571 .83 DIN 376 • • •

TPG M-27X3.0-M M27 3.000 6.299 1.417 - .787 4 .630 .94 DIN 376 • • •

TPG M-30X3.5-M M30 3.500 7.087 1.575 - .866 4 .709 1.04 DIN 376 • • •

• For user guide and cutting conditions, see pages 374-396

(1) Pitch in mm

(2) Number of flutes

(3) Torque key size

ISCAR

398