Page 32 - ISCAR TAPS

P. 32

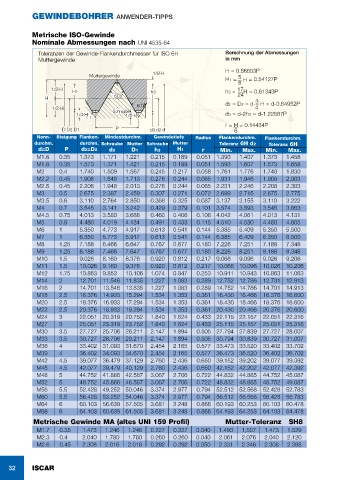

GEWINDEBOHRER ANWENDER-TIPPS

Metrische ISO-Gewinde

Nominale Abmessungen nach UNI 4535-64

Toleranzen der Gewinde-Flankendurchmesser für ISO 6H Berechnung der Abmessungen

Muttergewinde in mm

1/8·H H = 0.86603P

Muttergewinde 5

H1 = H = 0.54127P

8

1/2·H H1 h3 h3 = 17 H = 0.61343P

H 60ϒ 24

3

d2 = D2 = d- H = d-0.64952P

60ϒ

1/2·H 4

1/4·H Schraube d3 = d-2h3 = d-1.22687P

1/6·H

r

r = H = 0.14434P

DD2 D1 P d3 d2 d 6

Nenn- Steigung Flanken- Mindestdurchm. Gewindetiefe Radius Flankendurchm. Flankendurchm.

durchm. durchm. Schraube Mutter Schraube Mutter Toleranz 6H d2 Toleranz 6H

d=D P d2=D2 d3 D1 h3 H1 r Min. Max. Min. Max.

M1.6 0.35 1.373 1.171 1.221 0.215 0.189 0.051 1.393 1.407 1.373 1.458

M1.8 0.35 1.573 1.371 1.421 0.215 0.189 0.051 1.593 1.607 1.573 1.658

M2 0.4 1.740 1.509 1.567 0.245 0.217 0.058 1.761 1.776 1.740 1.830

M2.2 0.45 1.908 1.648 1.713 0.276 0.244 0.065 1.931 1.946 1.908 2.003

M2.5 0.45 2.208 1.948 2.013 0.276 0.244 0.065 2.231 2.246 2.208 2.303

M3 0.5 2.675 2.387 2.459 0.307 0.271 0.072 2.699 2.715 2.675 2.775

M3.5 0.6 3.110 2.764 2.850 0.368 0.325 0.087 3.137 3.155 3.110 3.222

M4 0.7 3.545 3.141 3.242 0.429 0.379 0.101 3.574 3.593 3.545 3.663

M4.5 0.75 4.013 3.580 3.688 0.460 0.406 0.108 4.042 4.061 4.013 4.131

M5 0.8 4.480 4.019 4.134 0.491 0.433 0.115 4.510 4.530 4.480 4.605

M6 1 5.350 4.773 4.917 0.613 0.541 0.144 5.385 5.409 5.350 5.500

M7 1 6.350 5.773 5.917 0.613 0.541 0.144 6.385 6.409 6.350 6.500

M8 1.25 7.188 6.466 6.647 0.767 0.677 0.180 7.226 7.251 7.188 7.348

M9 1.25 8.188 7.466 7.647 0.767 0.677 0.180 8.226 8.251 8.188 8.348

M10 1.5 9.026 8.160 8.376 0.920 0.812 0.217 9.068 9.096 9.026 9.206

M11 1.5 10.026 9.160 9.376 0.920 0.812 0.217 10.068 10.096 10.026 10.206

M12 1.75 10.863 9.853 10.106 1.074 0.947 0.253 10.911 10.943 10.863 11.063

M14 2 12.701 11.546 11.835 1.227 1.083 0.289 12.752 12.786 12.701 12.913

M16 2 14.701 13.546 13.835 1.227 1.083 0.289 14.752 14.786 14.701 14.913

M18 2.5 16.376 14.933 15.294 1.534 1.353 0.361 16.430 16.466 16.376 16.600

M20 2.5 18.376 16.933 17.294 1.534 1.353 0.361 18.430 18.466 18.376 18.600

M22 2.5 20.376 18.933 19.294 1.534 1.353 0.361 20.430 20.466 20.376 20.600

M24 3 22.051 20.319 20.752 1.840 1.624 0.433 22.115 22.157 22.051 22.316

M27 3 25.051 23.319 23.752 1.840 1.624 0.433 25.115 25.157 25.051 25.316

M30 3.5 27.727 25.706 26.211 2.147 1.894 0.505 27.794 27.839 27.727 28.007

M33 3.5 30.727 28.706 29.211 2.147 1.894 0.505 30.794 30.839 30.727 31.007

M36 4 33.402 31.093 31.670 2.454 2.165 0.577 33.473 33.520 33.402 33.702

M39 4 36.402 34.093 34.670 2.454 2.165 0.577 36.473 36.520 36.402 36.702

M42 4.5 39.077 36.479 37.129 2.760 2.436 0.650 39.152 39.202 39.077 39.392

M45 4.5 42.077 39.479 40.129 2.760 2.436 0.650 42.152 42.202 42.077 42.392

M48 5 44.752 41.866 42.587 3.067 2.706 0.722 44.832 44.885 44.752 45.087

M52 5 48.752 45.866 46.587 3.067 2.706 0.722 48.832 48.885 48.752 49.087

M56 5.5 52.428 49.252 50.046 3.374 2.977 0.794 52.512 52.568 52.428 52.783

M60 5.5 56.428 53.252 54.046 3.374 2.977 0.794 56.512 56.568 56.428 56.783

M64 6 60.103 56.639 57.505 3.681 3.248 0.866 60.193 60.253 60.103 60.478

M68 6 64.103 60.639 61.505 3.681 3.248 0.866 64.193 64.253 64.103 64.478

Metrische Gewinde MA (altes UNI 159 Profil) Mutter-Toleranz SH8

M1.7 0.35 1.473 1.246 1.246 0.227 0.227 0.040 1.493 1,507 1.473 1.529

M2.3 0.4 2.040 1.780 1.780 0.260 0.260 0.040 2.061 2.076 2.040 2.120

M2.6 0.45 2.308 2.016 2.016 0.292 0.292 0.050 2.331 2.346 2.308 2.388

32 ISCAR