Page 34 - ISCAR TAPS

P. 34

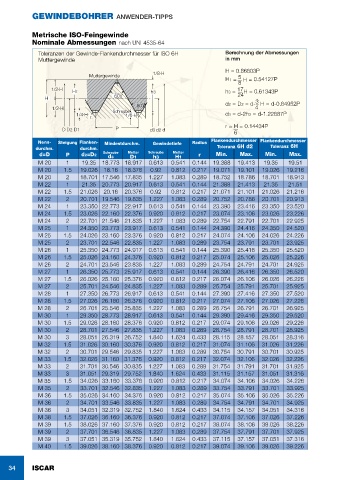

GEWINDEBOHRER ANWENDER-TIPPS

Metrische ISO-Feingewinde

Nominale Abmessungen nach UNI 4535-64

Toleranzen der Gewinde-Flankendurchmesser für ISO 6H Berechnung der Abmessungen

Muttergewinde in mm

1/8·H H = 0.86603P

Muttergewinde 5

H1 = H = 0.54127P

8

1/2·H H1 h3 h3 = 17 H = 0.61343P

H 60ϒ 24

3

d2 = D2 = d- H = d-0.64952P

60ϒ

1/2·H 4

1/4·H Schraube d3 = d-2h3 = d-1.22687P

1/6·H

r

DD2 D1 P d3 d2 d r = H = 0.14434P

6

Nenn- Steigung Flanken- Mindestdurchm. Gewindetiefe Radius Flankendurchmesser Flankendurchmesser

Toleranz 6H

durchm. durchm. Toleranz 6H d2

d=D P d2=D2 Schraube Mutter Schraube Mutter r Min. Max. Min. Max.

D1

H1

h3

d3

M 20 1 19.35 18.773 18.917 0.613 0.541 0.144 19.388 19.413 19.35 19.51

M 20 1.5 19.026 18.16 18.376 0.92 0.812 0.217 19.071 19.101 19.026 19.216

M 20 2 18.701 17.546 17.835 1.227 1.083 0.289 18.752 18.786 18.701 18.913

M 22 1 21.35 20.773 20.917 0.613 0.541 0.144 21.388 21.413 21.35 21.51

M 22 1.5 21.026 20.16 20.376 0.92 0.812 0.217 21.071 21.101 21.026 21.216

M 22 2 20.701 19.546 19.835 1.227 1.083 0.289 20.752 20.786 20.701 20.913

M 24 1 23.350 22.773 22.917 0.613 0.541 0.144 23.390 23.416 23.350 23.520

M 24 1.5 23.026 22.160 22.376 0.920 0.812 0.217 23.074 23.106 23.026 23.226

M 24 2 22.701 21.546 21.835 1.227 1.083 0.289 22.754 22.791 22.701 22.925

M 25 1 24.350 23.773 23.917 0.613 0.541 0.144 24.390 24.416 24.350 24.520

M 25 1.5 24.026 23.160 23.376 0.920 0.812 0.217 24.074 24.106 24.026 24.226

M 25 2 23.701 22.546 22.835 1.227 1.083 0.289 23.754 23.791 23.701 23.925

M 26 1 25.350 24.773 24.917 0.613 0.541 0.144 25.390 25.416 25.350 25.520

M 26 1.5 25.026 24.160 24.376 0.920 0.812 0.217 25.074 25.106 25.026 25.226

M 26 2 24.701 23.546 23.835 1.227 1.083 0.289 24.754 24.791 24.701 24.925

M 27 1 26.350 25.773 25.917 0.613 0.541 0.144 26.390 26.416 26.350 26.520

M 27 1.5 26.026 25.160 25.376 0.920 0.812 0.217 26.074 26.106 26.026 26.226

M 27 2 25.701 24.546 24.835 1.227 1.083 0.289 25.754 25.791 25.701 25.925

M 28 1 27.350 26.773 26.917 0.613 0.541 0.144 27.390 27.416 27.350 27.520

M 28 1.5 27.026 26.160 26.376 0.920 0.812 0.217 27.074 27.106 27.026 27.226

M 28 2 26.701 25.546 25.835 1.227 1.083 0.289 26.754 26.791 26.701 26.925

M 30 1 29.350 28.773 28.917 0.613 0.541 0.144 29.390 29.416 29.350 29.520

M 30 1.5 29.026 28.160 28.376 0.920 0.812 0.217 29.074 29.106 29.026 29.226

M 30 2 28.701 27.546 27.835 1.227 1.083 0.289 28.754 28.791 28.701 28.925

M 30 3 28.051 26.319 26.752 1.840 1.624 0.433 28.115 28.157 28.051 28.316

M 32 1.5 31.026 30.160 30.376 0.920 0.812 0.217 31.074 31.106 31.026 31.226

M 32 2 30.701 29.546 29.835 1.227 1.083 0.289 30.754 30.791 30.701 30.925

M 33 1.5 32.026 31.160 31.376 0.920 0.812 0.217 32.074 32.106 32.026 32.226

M 33 2 31.701 30.546 30.835 1.227 1.083 0.289 31.754 31.791 31.701 31.925

M 33 3 31.051 29.319 29.752 1.840 1.624 0.433 31.115 31.157 31.051 31.316

M 35 1.5 34.026 33.160 33.376 0.920 0.812 0.217 34.074 34.106 34.026 34.226

M 35 2 33.701 32.546 32.835 1.227 1.083 0.289 33.754 33.791 33.701 33.925

M 36 1.5 35.026 34.160 34.376 0.920 0.812 0.217 35.074 35.106 35.026 35.226

M 36 2 34.701 33.546 33.835 1.227 1.083 0.289 34.754 34.791 34.701 34.925

M 36 3 34.051 32.319 32.752 1.840 1.624 0.433 34.115 34.157 34.051 34.316

M 38 1.5 37.026 36.160 36.376 0.920 0.812 0.217 37.074 37.106 37.026 37.226

M 39 1.5 38.026 37.160 37.376 0.920 0.812 0.217 38.074 38.106 38.026 38.226

M 39 2 37.701 36.546 36.835 1.227 1.083 0.289 37.754 37.791 37.701 37.925

M 39 3 37.051 35.319 35.752 1.840 1.624 0.433 37.115 37.157 37.051 37.316

M 40 1.5 39.026 38.160 38.376 0.920 0.812 0.217 39.074 39.106 39.026 39.226

34 ISCAR