Page 33 - ISCAR TAPS

P. 33

GEWINDEBOHRER ANWENDER-TIPPS

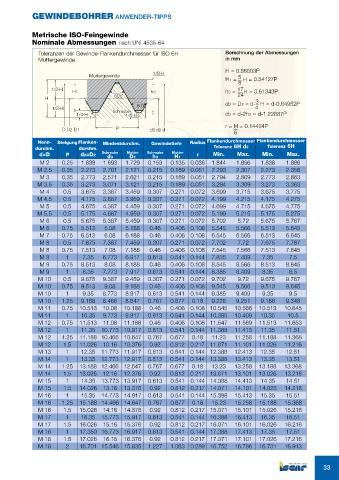

Metrische ISO-Feingewinde

Nominale Abmessungen nach UNI 4535-64

Toleranzen der Gewinde-Flankendurchmesser für ISO 6H Berechnung der Abmessungen

Muttergewinde in mm

1/8·H H = 0.86603P

Muttergewinde 5

H1 = H = 0.54127P

8

1/2·H H1 h3 h3 = 17 H = 0.61343P

H 60ϒ 24

3

d2 = D2 = d- H = d-0.64952P

60ϒ

1/2·H 4

1/4·H Schraube d3 = d-2h3 = d-1.22687P

1/6·H

r

DD2 D1 P d3 d2 d r = H = 0.14434P

6

Nenn- Steigung Flanken- Mindestdurchm. Gewindetiefe Radius Flankendurchmesser Flankendurchmesser

durchm. durchm. Toleranz 6H d2 Toleranz 6H

d=D P d2=D2 Schraube Mutter Schraube Mutter r Min. Max. Min. Max.

H1

D1

h3

d3

M 2 0.25 1.838 1.693 1.729 0.153 0.135 0.036 1.844 1.856 1.838 1.886

M 2.5 0.35 2.273 2.701 2.121 0.215 0.189 0.051 2.293 2.307 2.273 2.358

M 3 0.35 2.773 2.571 2.621 0.215 0.189 0.051 2.794 2.809 2.773 2.863

M 3.5 0.35 3.273 3.071 3.121 0.215 0.189 0.051 3.294 3.309 3.273 3.363

M 4 0.5 3.675 3.387 3.459 0.307 0.271 0.072 3.699 3.715 3.675 3.775

M 4.5 0.5 4.175 3.887 3.959 0.307 0.271 0.072 4.199 4.215 4.175 4.275

M 5 0.5 4.675 4.387 4.459 0.307 0.271 0.072 4.699 4.715 4.675 4.775

M 5.5 0.5 5.175 4.887 4.959 0.307 0.271 0.072 5.199 5.215 5.175 5.275

M 6 0.5 5.675 5.387 5.459 0.307 0.271 0.072 5.702 5.72 5.675 5.787

M 6 0.75 5.513 5.08 5.188 0.46 0.406 0.108 5.545 5.566 5.513 5.645

M 7 0.75 6.513 6.08 6.188 0.46 0.406 0.108 6.545 6.566 6.513 6.645

M 8 0.5 7.675 7.387 7.459 0.307 0.271 0.072 7.702 7.72 7.675 7.787

M 8 0.75 7.513 7.08 7.188 0.46 0.406 0.108 7.545 7.566 7.513 7.645

M 8 1 7.35 6.773 6.917 0.613 0.541 0.144 7.835 7.409 7.35 7.5

M 9 0.75 8.513 8.08 8.188 0.46 0.406 0.108 8.545 8.566 8.513 8.645

M 9 1 8.35 7.773 7.917 0.613 0.541 0.144 8.385 8.409 8.35 8.5

M 10 0.5 9.675 9.387 9.459 0.307 0.271 0.072 9.702 9.72 9.675 9.787

M 10 0.75 9.513 9.08 9.188 0.46 0.406 0.108 9.545 9.566 9.513 9.645

M 10 1 9.35 8.773 8.917 0.613 0.541 0.144 9.385 9.409 9.35 9.5

M 10 1.25 9.188 8.466 8.647 0.767 0.677 0.18 9.226 9.251 9.188 9.348

M 11 0.75 10.513 10.08 10.188 0.46 0.406 0.108 10.545 10.566 10.513 10.645

M 11 1 10.35 9.773 9.917 0.613 0.541 0.144 10.385 10.409 10.35 10.5

M 12 0.75 11.513 11.08 11.188 0.46 0.406 0.108 11.547 11.569 11.513 11.653

M 12 1 11.35 10.773 10.917 0.613 0.541 0.144 11.388 11.413 11.35 11.51

M 12 1.25 11.188 10.466 10.647 0.767 0.677 0.18 11.23 11.258 11.188 11.368

M 12 1.5 11.026 10.16 10.376 0.92 0.812 0.217 11.071 11.101 11.026 11.216

M 13 1 12.35 11.773 11.917 0.613 0.541 0.144 12.388 12.413 12.35 12.51

M 14 1 13.35 12.773 12.917 0.613 0.541 0.144 13.388 13.413 13.35 13.51

M 14 1.25 13.188 12.466 12.647 0.767 0.677 0.18 13.23 13.258 13.188 13.368

M 14 1.5 13.026 12.16 12.376 0.92 0.812 0.217 13.071 13.101 13.026 13.216

M 15 1 14.35 13.773 13.917 0.613 0.541 0.144 14.388 14.413 14.35 14.51

M 15 1.5 14.026 13.16 13.376 0.92 0.812 0.217 14.071 14.101 14.026 14.216

M 16 1 15.35 14.773 14.917 0.613 0.541 0.144 15.388 15.413 15.35 15.51

M 16 1.25 15.188 14.466 14.647 0.767 0.677 0.18 15.23 15.258 15.188 15.368

M 16 1.5 15.026 14.16 14.376 0.92 0.812 0.217 15.071 15.101 15.026 15.216

M 17 1 16.35 15.773 15.917 0.613 0.541 0.144 16.388 16.413 16.35 16.51

M 17 1.5 16.026 15.16 15.376 0.92 0.812 0.217 16.071 16.101 16.026 16.216

M 18 1 17.350 16.773 16.917 0.613 0.541 0.144 17.388 17.413 17.35 17.51

M 18 1.5 17.026 16.16 16.376 0.92 0.812 0.217 17.071 17.101 17.026 17.216

M 18 2 16.701 15.546 15.835 1.227 1.083 0.289 16.752 16.786 16.701 16.913

33